PRODUCT

Calorised Lancing Pipes

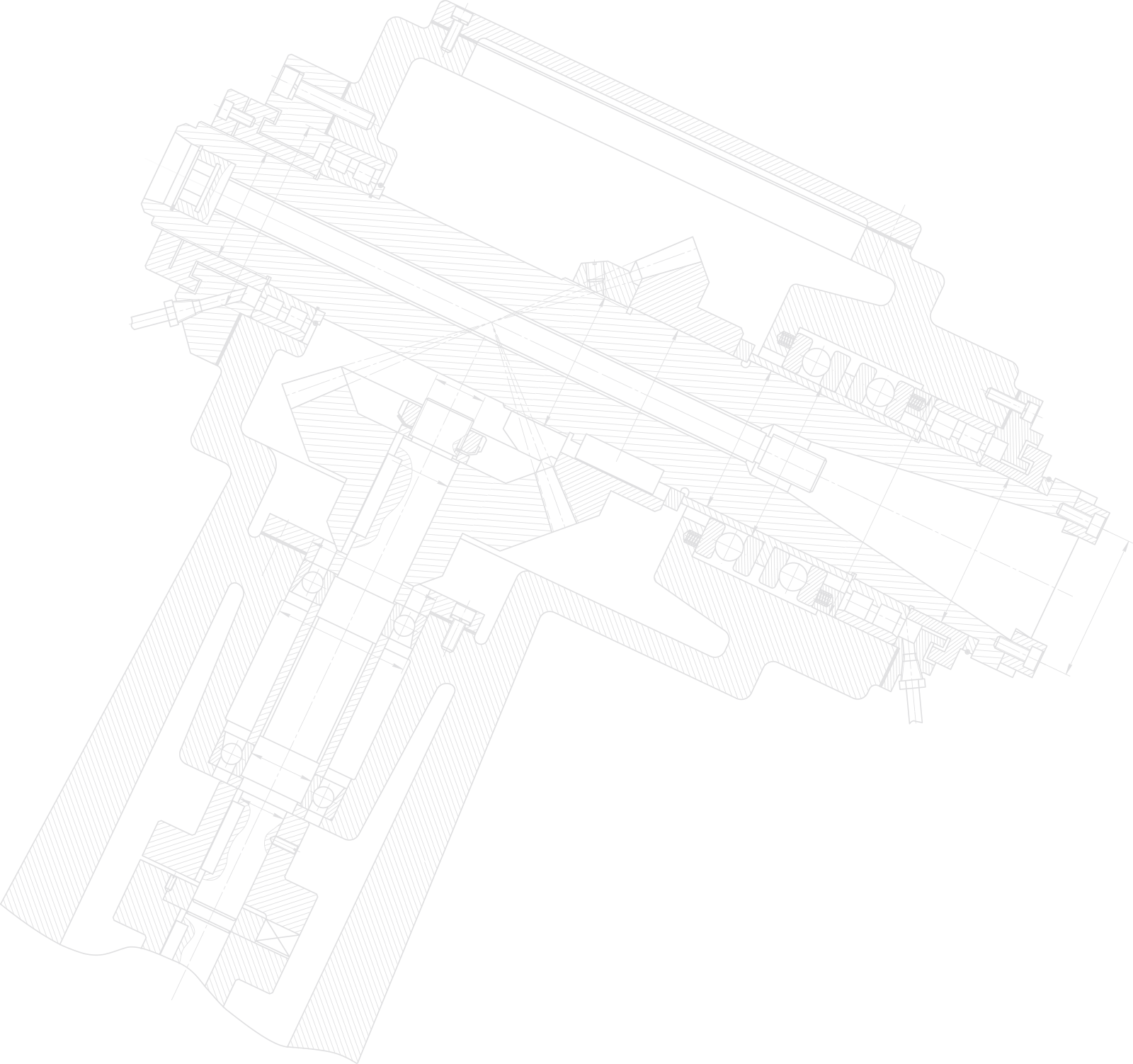

Calorised lance pipes are prepared by rendering Calorising finish to carbon steel in a thickness of 100-150 microns on both inner and outer surface. This is a aluminum diffusion treatment which promotes the fireproof properties of steel pipes. This diffusion is an intermetallic bond, which doesn’t get damaged either by mechanical working like bending or straightening or by high temperatures. In the case of ceramic coated pipes, oxidation takes place at that part of the surface in contact with the liquid metal.

Description

In the case of Calorised pipes, the metal existing at the surface of the diffused zone is oxidized to its respective oxide, which prevents the further progress of oxidation and also melting. Hence diffused, aluminum is oxidized to alumina, which has very high melting pint such as 20500C compared to the melting point of aluminum, which is 6580C.

This is the essential difference between ceramic coated pipes and joint Calorised pipes. A more effective result is obtained by ceramic coating on the metal diffused zone.

In the process of steel manufacturing by electric furnace, the consumption rate of lance pipes for oxygen injection show rather high ratio to high temperature and severe oxidation. In general, steel pipes are used as lance pipes for oxygen / carbon injection. If MS pipes are treated by this Calorised process, consumption rate of lance pipes will improve 6-7 times. The advantages of oxygen steel making process are:

- The exothermic reaction and agitation promote decarbonisation and heat rise in the furnace, while foaming slag can be

- Fusion of sub material can be accelerated

- Quality of steel will be

- As the process raises the temperature of furnace, it leads to saving in electric

- Selection of raw materials to be charged becomes

- The process raises the production capacity of an electric

- Hydrogen, Nitrogen and non-metallic inclusions can be eliminated through

- It makes it possible to recover chrome with the use high chrome steel

Additonal Information

- Savings in Electricity Cost equivalent to 1326 hrs/year.

- Savings in Labour Cost 1326 hrs/year.

- Higher yield equivalent to 1326 hrs/year.

- Lower Inventory

- Lesser space for storage of Calorised Lancing

Related Products

Carbon steel pipes

Cast Iron pipes

Vitrified clay pipes